Aluminium Extrusion

1

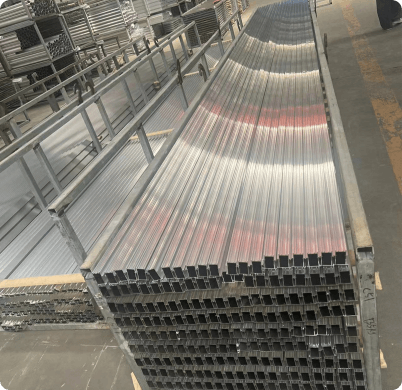

Aluminium profile extrusion is a process in which Aluminium billets are forced through a die to create specific shapes and profiles. The Aluminium billet is heated and placed into the extrusion press, where it is pushed through a steel die using high pressure. The die has openings that define the shape of the profile being produced.During the extrusion process, the Aluminium is softened by the heat and pressure, allowing it to flow through the die and take on the desired shape.

We currently ave 15 Aluminium extrusion presses, These machines can cater to various types of Aluminium profiles, ranging from plain sections to complex profiles with multiple cavities.We take pride in our ability to provide tailor-made solutions for our customers’ specific profile needs, using our advanced extrusion technology and expertise.

Aluminium Anodizing

2

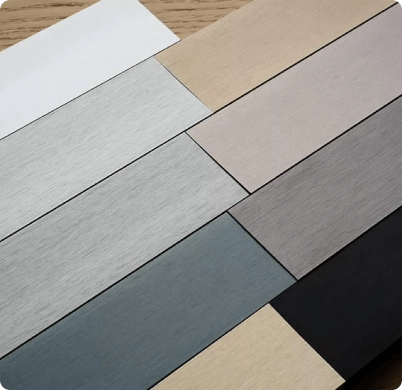

Anodized Aluminium is a robust electrochemical process that bolsters the corrosion resistance and surface hardness of Aluminium. This process forms a protective oxide film, offering superior weather and abrasion resistance. The process involves treating Aluminium products electrolytically in an electrolyte solution, yielding a dense, uniform oxide film. This film can be tailored with various colors and textures, providing both aesthetic appeal and functional properties.

we specialize in producing an extensive range of anodized colors, including silver, champagne, gold, bronze, black, gray, burgundy, and copper. These colors can enhance various surfaces, from matte to brushed finishes. Our anodized Aluminium products are the ideal choice for stylish furniture and modern kitchens. We are dedicated to delivering high-quality anodized Aluminium products that fulfill our customers’ unique needs and expectations.

Aluminium Polishing

3

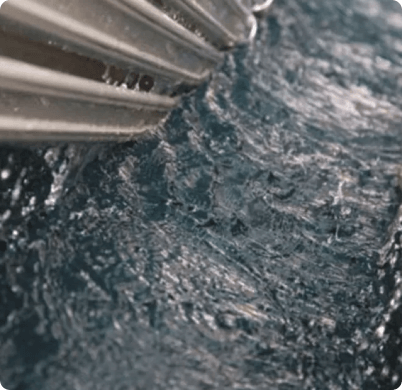

Polishing is an advanced surface treatment method that makes the surface of Aluminium products smooth and shiny like a mirror, improving the decorative effect of Aluminium products . It can also add higher commercial value to Aluminium products and meet the demand for Aluminium products with a bright surface in the furniture industry.

We offers two colored polishing technologies for Aluminium products: mechanical polishing and chemical polishing. Mechanical polishing involves removing extrusion lines using flax wheels and then polishing with a cloth wheel. Chemical polishing involves putting the profiles into oxidized anodized and acid grooves, resulting in a dense chromate layer on the surface. The available polishing profile colors include silver, champagne, bronze, golden, grey, and violet gold. Etc.

Brush Aluminium

4

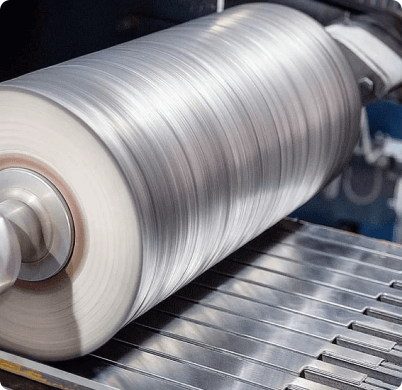

In the furniture Aluminium profile market, it is indeed common to see hairline finishes or vertical stripes on the surface of Aluminium profiles, especially in applications such as wardrobes and cabinets.

To achieve these brushed finishes, a process involving rotating nylon wheels on a motor-driven main shaft is commonly used. Different types of nylon wheels can be used to achieve different brushed finishes or to achieve a deeper or lighter edge treatment. This process effectively removes die lines, scratches, and marks from the surface of Aluminium profiles while enhancing their appearance.

After the brushing process, a common post-processing method is to perform anodizing with a matte finish or chemical polishing with a glossy finish. This allows for a wider range of color options, such as champagne, black, brown, iron grey, gold, and more. These finishes not only provide aesthetic appeal but also offer additional protection to the Aluminium profiles, enhancing their durability and resistance to corrosion.

Wood Grain

5

The wood grain surface treatment achieved through sublimation opens up a wide range of possibilities for creating different styles and designs in furniture and interior design applications. It allows for the creation of realistic wood-like finishes on Aluminium profiles, providing the aesthetic appeal of wood with the added benefits of Aluminium, such as durability, lightweight, and resistance to moisture and pests.

we offer sublimation as one of our surface treatment options for Aluminium profiles. Our sublimation process ensures high-quality finishes that replicate the appearance of wood or other materials, providing endless design possibilities for furniture and interior applications.

Powder Coating

6

Electrostatic coating is a common surface treatment method for Aluminium profiles, which can be divided into powder coating and Waterborne fluorocarbon. Powder coating is known for its high efficiency, energy-saving, and environmental-friendly properties, with good coating performance. However, the surface may not be as soft. On the other hand, Waterborne fluorocarbon spraying offers high brightness, thin and stable color coating, strong weather resistance, and long-lasting color retention.In the future, the furniture Aluminium profile market is expected to lean towards soft-touch Waterborne fluorocarbon coatings. These coatings provide a rubbery or velvety feel to the surface, enhancing the tactile experience. Along with their scratch and stain resistance properties, soft-touch Waterborne fluorocarbon coatings offer an added level of durability and aesthetics, making them highly desirable for furniture applications.

we are committed to staying at the forefront of surface treatment technologies. We offer a range of coating options, including powder coating and Waterborne fluorocarbon spraying, to meet the diverse needs and preferences of our customers.

CNC Machining

7

we primarily utilizes CNC aluminium profile machining centers and punching machines for further processing and treatment of aluminium profiles. offer cutting, drilling, punching, milling, and other processes to meet specific needs and applications. We specialize in providing deep processing of aluminium extrusions, such as handles and door frame systems, in various sizes for the furniture wardrobe industry and cabinet manufacturers and offer surface services after processing, including high polishing, brushed treatment, anodizing, and water-based fluorocarbon coating in a variety of colors.

Business and Services

8

No matter big or small orders,we treat equally. Once we decide to accept your inquiry we will try the best to finish perfectly.All our service team members have at least 5 years working experience in export trade. They have great communication skill and get client’s requirement easily.

Should you need any further info or assistance, please do not hesitate to contact our team.

Do You Have Questions Or Want to Place an Order?

We Are Always in Touch