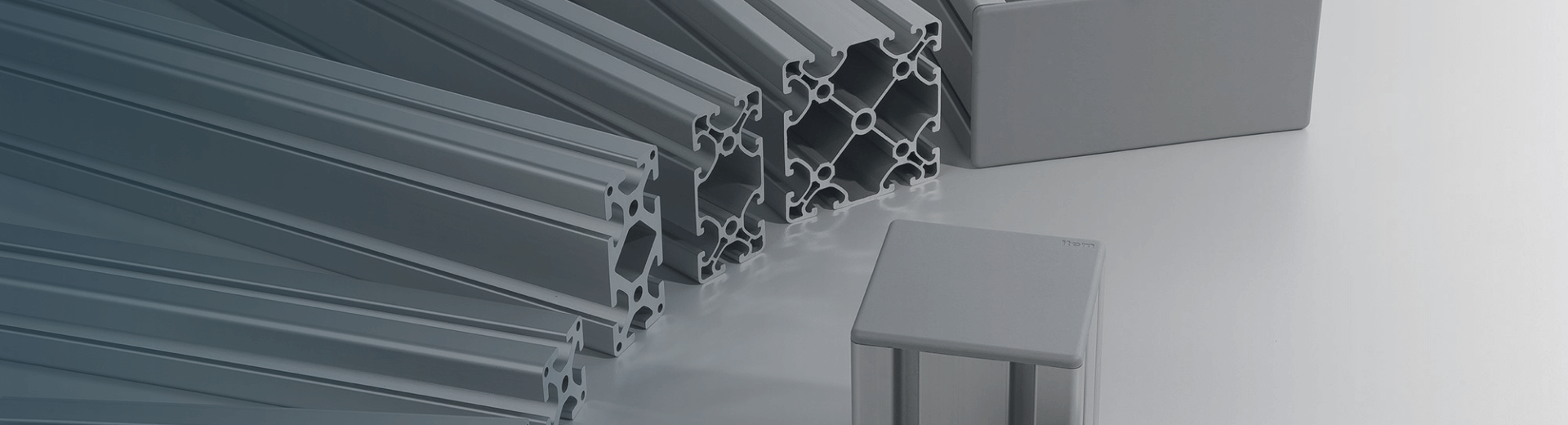

| Aluminium alloy | 6063、6005、6060、6061、6165、6082、6351、 6013、5083、7005、7075 |

| Temper | T4、T5、T6 |

| Thickness | Mostly from 1.0 ~ 2.0 mm,Min at 0.5 mm; Max at 10 mm or according to drawing design |

| Length | 500 mm < L < 9000 mm |

| Surface treatment & color | a) Anodized & electrophoresis: silver、champagne、golden、bronze、brown、black b) Matt electro-deposition: golden、grey、silver、black c)Powder coated:white、blue、yellow、brown or customized d) Wood transfer:oak、wilow、teak、yellow pear、walnut or customized e) PVDF double or triple coating: white、grey、brown、black or customized f) Polish & brush:silver、champagne、bronze、golden |

| Profile extrude size: | Max width: 400 mm; Max diameter: 290 mm |

| Factory capacity: | Monthly output about 4000 tons; Max monthly capacity about 6000 tons. |

| Production standard | GB5237-2008 |

| Lead time | Mould making 7 days; Mill finish 10 days; Powder coat 15 days; Anodize & electrophoresis 18 days; other surface about 20 days. |

| Dimensional deviations info(6063-T5) | Angle deviation:±1.0°Plane clearance: less than 0.37mmBending degree: less than 0.3mmfrom 300mmTwist degree: less than 1.7mm from 1m profileCutting angle: less than 2° |

| Mechanical characteristic (6063-T5) | Vickers hardness (HV)≥58Webster hardness (HW)≥8Tensile strength: no less than 160 N/mm2 |

| Anodizing characteristic | Average thickness of anodize film: no less than 10 μmPartial thickness of anodize film: no less than 8 μmAnodize sealing quality: no less than 30 mg/dm2Hardness (Pential scratch testing): ≥ 3HCASS test (24h):≥ 9 gradeAlkali resistance(24h):no less than 9 gradeWear resistance(sand drop testing): ≥300 g/μm |

| Powder coating characteristic | Coating indentation hardness: ≥ 80Coating thickness: 60 ~ 120 μmSmallest local thickness: > 40 μmadhension (dry、wet、boiling water): 0 gradeWear resistance(sand drop testing): ≥0.8 L/μmHydrochloric Acid resistance: no blistering and obvious changeSolvent resistance: ≥ 3 gradeDetergent resistance: no blistering, no loss of film adhension and obvious changeMortar resistance: no loss of film adhension and no visual change in appearanceBoiling water resistance: no air bubble、 wrinkle、cracks、falls off and color change on test specimen |

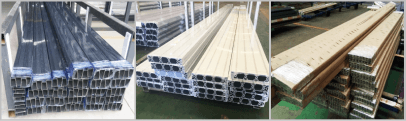

1) Each profiles surface protected by transparent or logo film, and several profile wrap to be bundle by shrink film.

2) Each profiles interleaf by EPE form, and several profile wrap to be bundle by shrink film.

3) Each profiles surface protect by film or interleaf by EPE form, and several profile roll by paper.

Step 1: Dozens of bundle alu profile put on the wood pallet base, and fixed by strip film.

Step 2: Cover the alu profiles by thick paper and wrap by shrink film.

Step 3: Surrounded the pallet by numbers of wood strip and fixed to be firmed pallet by pvc or iron strip.

Each profile interleaf by EPE form or pack by plastic bag, dozens of alu profile put in carton and seal & strengthen by tape.

We not only has 50,000+ molds to meet different customers, but also accepts customized services, just provide aluminum profile drawings.

Contact us